Mass Transit & Railway Systems

BENEFITS

Tough. Durable. Versatile.

Vitreous enamel will not rust, is resistant to chemical attack, abrasion and fire as well as being more durable than any other architectural cladding coating.

Its versatility enables custom designs of all shapes and dimensions, the use of graphics and logos as well as a virtually unlimited colour range.

Non Static

Does not collect dust or allergens.

Fire Resistance

Vitreous enameled panels have an ignitability index of 0, spread of flame index of 0, heat evolved index of 0 and smoke developed index of 1 according to AS NZ 1530.3 and are non combustible to BS 476 Part 4, have a fire propagation index of 0 to BS 476 Part 6 and have a Class 1 spread of flame classification to BS 476 Part 7.

They are an ideal replacement for combustible cladding and have a superior fire performance to all main architectural cladding materials.

Graffiti Resistant

Non stick, non porous, chemical resistant, extremely hard and color fast. Any painted or written graffiti on the coating can be entirely removed without affecting the performance of the panel. No stains. No discolouration.

Thermal Shock Resistance

Vitreous enameled coated steel will withstand rapid cooling by water spray from +400┬░C to normal room temperatures over a 30 second period.

Safety

The resistance of vitreous enameled steel to impact and distortion under extreme conditions provide further significant safety advantages in applications such as tunnels and claddings in public areas.

Non Porous

Like glass, vitreous enamel is completely non porous which prevents harmful bacteria or residual chemicals from being absorbed into the enamel surface. When an enamel surface is cleaned with anti-bacterial solutions it is truly sterile and germ free.

Printable Coating

Vitreous enamel panels can be silkscreened or direct printed with high resolution multi-coloured graphics.

Images or graphics will be a vitreous enamel coating with the same durability and performance characteristics.

Electrical Safety

Vitreous enamel panels can assist with insulating against electrical currents or, if the enamel is penetrated, can be used as an earth point.

Dielectric strength of ordinary vitreous enamels will range from 200 to 500 volts per mil with an average of 4 to 6 mm total thickness.

Environmental Safety

The production of VE panels is an environmentally friendly process that does not involve harmful substances.

The panels are made from non toxic materials including glass and steel.

Materials are not harmful to the environment and are recyclable. The VE coating increases the lifespan of the original steel many times thereby reducing waste and the number of times the steel needs to be reprocessed.  VE Panels release no toxic fumes.

Non stick, easy to clean

High lubricity, non stick and non porous make it very easy to clean with a mild detergent solution or anti-septic chemical cleaners.

High Impact Resistance

The physical strength of the steel, coating and panel backing enable vitreous enameled panels to withstand deformation and damage due to impact. Panels are quick to install and easily replaced.

Lower Maintenance Costs

Non Stick and non static vitreous enamel attracts less dirt and harmful bacteria. Extremely high abrasive resistance ensures no scratching during regular cleaning cycles and therefore no loss in anti-bacterial quality of the smooth vitreous enamel coating. Panels can easily be kept sterile with no loss in quality over time.

High Chemical Resistance

Vitreous enamels are formulated with relatively inert inorganic oxides. This provides an impervious surface that is highly resistant to chemicals that may be used in medical, manufacturing or convenience clean room environments. This includes: Strong Acids at any temperature up to 191⁰C (with the only exception of hydrofluoric acid). Alkalis : Up to maximum pH of 12 at 100⁰C. Also including organic acids and solvents, oils and soil corrosion.

High Resistance to Abrasion

A combination of very high lubricity and extreme surface hardness gives vitreous enamel unusually high abrasive resistance when compared to other cladding surfaces. On the Moh Hardness Scale : Diamond =10, Aluminium or Sheet Steel=3 Resin Coatings = 2.5 – 3 Vitreous Enamel = 5 to 6. This high abrasive resistance ensures no scratching during regular cleaning cycles and no loss in anti bacterial quality of the smooth vitreous enamel coating.

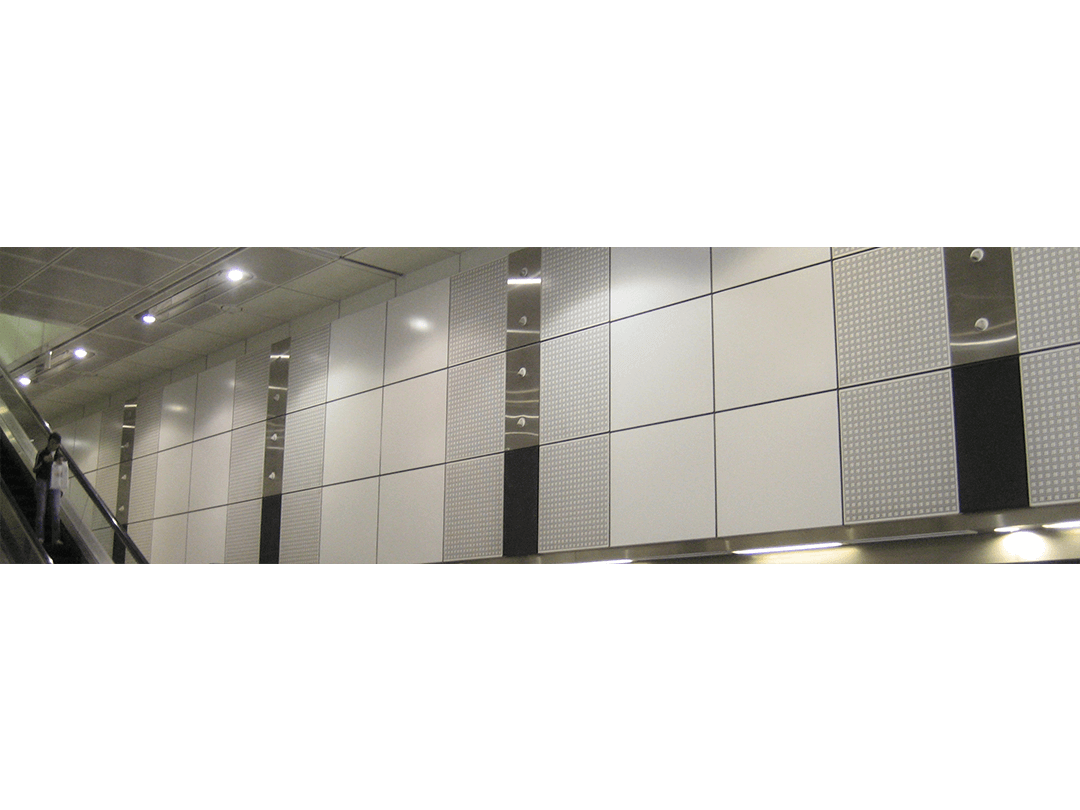

First choice worldwide for the underground rail and subway environment.

Vitreous enamel coating is naturally reflective and extremely durable providing an ideal finish for highly trafficked public infrastructure applications.

Ceratec has extensive experience in the design, manufacture and installation of vitreous enamel panels for underground mass transit railway systems in Hong Kong and Singapore as well as for railway applications in Australia and United Kingdom.

BENEFITS

Tough. Durable. Versatile.

Vitreous enamel will not rust, is resistant to chemical attack, abrasion and fire as well as being more durable than any other architectural cladding coating.

Its versatility enables custom designs of all shapes and dimensions, the use of graphics and logos as well as a virtually unlimited colour range.

Non Static

Does not collect dust or allergens.

Fire Resistance

Vitreous enameled panels have an ignitability index of 0, spread of flame index of 0, heat evolved index of 0 and smoke developed index of 1 according to AS NZ 1530.3 and are non combustible to BS 476 Part 4, have a fire propagation index of 0 to BS 476 Part 6 and have a Class 1 spread of flame classification to BS 476 Part 7.

They are an ideal replacement for combustible cladding and have a superior fire performance to all main architectural cladding materials.

Graffiti Resistant

Non stick, non porous, chemical resistant, extremely hard and color fast. Any painted or written graffiti on the coating can be entirely removed without affecting the performance of the panel. No stains. No discolouration.

Thermal Shock Resistance

Vitreous enameled coated steel will withstand rapid cooling by water spray from +400┬░C to normal room temperatures over a 30 second period.

Safety

The resistance of vitreous enameled steel to impact and distortion under extreme conditions provide further significant safety advantages in applications such as tunnels and claddings in public areas.

Non Porous

Like glass, vitreous enamel is completely non porous which prevents harmful bacteria or residual chemicals from being absorbed into the enamel surface. When an enamel surface is cleaned with anti-bacterial solutions it is truly sterile and germ free.

Printable Coating

Vitreous enamel panels can be silkscreened or direct printed with high resolution multi-coloured graphics.

Images or graphics will be a vitreous enamel coating with the same durability and performance characteristics.

Electrical Safety

Vitreous enamel panels can assist with insulating against electrical currents or, if the enamel is penetrated, can be used as an earth point.

Dielectric strength of ordinary vitreous enamels will range from 200 to 500 volts per mil with an average of 4 to 6 mm total thickness.

Environmental Safety

The production of VE panels is an environmentally friendly process that does not involve harmful substances.

The panels are made from non toxic materials including glass and steel.

Materials are not harmful to the environment and are recyclable. The VE coating increases the lifespan of the original steel many times thereby reducing waste and the number of times the steel needs to be reprocessed.  VE Panels release no toxic fumes.

Non stick, easy to clean

High lubricity, non stick and non porous make it very easy to clean with a mild detergent solution or anti-septic chemical cleaners.

High Impact Resistance

The physical strength of the steel, coating and panel backing enable vitreous enameled panels to withstand deformation and damage due to impact. Panels are quick to install and easily replaced.

Lower Maintenance Costs

Non Stick and non static vitreous enamel attracts less dirt and harmful bacteria. Extremely high abrasive resistance ensures no scratching during regular cleaning cycles and therefore no loss in anti-bacterial quality of the smooth vitreous enamel coating. Panels can easily be kept sterile with no loss in quality over time.

High Chemical Resistance

Vitreous enamels are formulated with relatively inert inorganic oxides. This provides an impervious surface that is highly resistant to chemicals that may be used in medical, manufacturing or convenience clean room environments. This includes: Strong Acids at any temperature up to 191⁰C (with the only exception of hydrofluoric acid). Alkalis : Up to maximum pH of 12 at 100⁰C. Also including organic acids and solvents, oils and soil corrosion.

High Resistance to Abrasion

A combination of very high lubricity and extreme surface hardness gives vitreous enamel unusually high abrasive resistance when compared to other cladding surfaces. On the Moh Hardness Scale : Diamond =10, Aluminium or Sheet Steel=3 Resin Coatings = 2.5 - 3 Vitreous Enamel = 5 to 6. This high abrasive resistance ensures no scratching during regular cleaning cycles and no loss in anti bacterial quality of the smooth vitreous enamel coating.